We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Janome Bench Top Robot

Sold

Wanted

SKU

J090

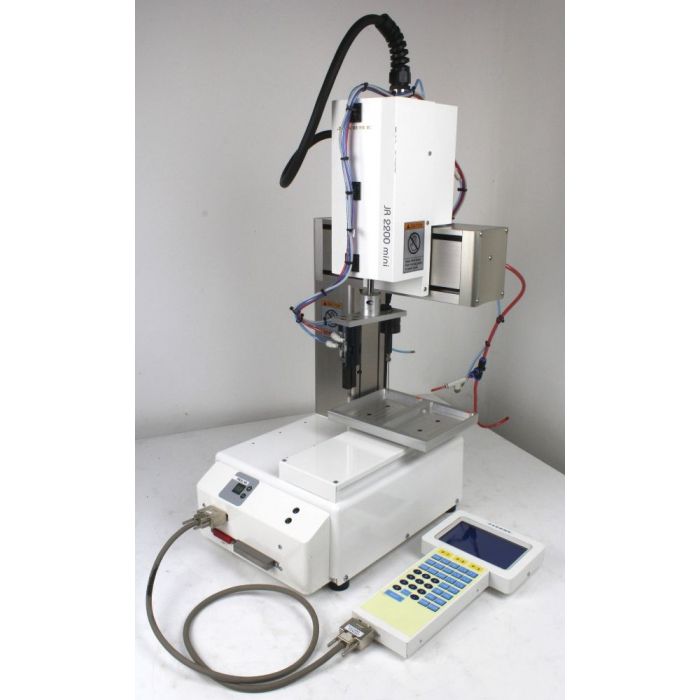

Janome Bench Top Robot

Multi discipline Robot

Janome JR 2200 Mini XYZ Soldering/Dispensing/screwing Robot

Includes Teaching pendant and Dispensing Equipment as pictured.

Also with the Dust free Cabinet made in perspex and aluminium Frame.

Also with the Dust free Cabinet made in perspex and aluminium Frame.

This was pulled from a Research Laboratory. These are still sold by Jenome, so parts and maintenance are readily available.

This Instrument is currently set up with liquid dispensing for 2 Microplates. We have tested the machine and it responds appropriatley to the programmes pre-installed and a video of the robot working can be found at https://youtu.be/iaO03iUIqMM

Janome JR2000N Desktop Robots provide companies with a solid platform to implement multiple application solutions for manufacturing. Dispensing, Screw Fastening, Soldering, Pick & Place, PCB Routing and Cleaning are just some of the solutions available.

Dialog based operating software makes programming a snap, eliminating complicated programming language. The robot easily performs 3-dimensional linear and arc interpolations with positional repeatability of +- 0.01mm. The JR2000N expands worker productivity by allowing one employee to operate several systems at once.

Easy Setup & Quick Start-up

The desktop robot’s interactive dialog teaching method is easy and eliminates the need for a complex programming language.

Reliable Precision

The sturdy, aluminum alloy die cast single structure in both H and L shape upper bodies provides the stability necessary for high precision repeatable accuracy.

The sturdy, aluminum alloy die cast single structure in both H and L shape upper bodies provides the stability necessary for high precision repeatable accuracy.

Compact Size & Flexibility

The compact size of the tabletop robot not only saves space but enables installation in smaller workshops. It’s small footprint, light weight and built-in controller enables the construction of a flexible production system.

The compact size of the tabletop robot not only saves space but enables installation in smaller workshops. It’s small footprint, light weight and built-in controller enables the construction of a flexible production system.

Professional Program Environment

The JR2000N Benchtop Robot has a broad variety of point jobs, variables and COM commands.

The JR2000N Benchtop Robot has a broad variety of point jobs, variables and COM commands.

Needle Adjustment

Simple, Fast, Automatically Corrects Position

When a needle is changed, the adjuster uses the previously registered program data to automatically adjust tool-tip position. It is also possible to run periodic adjustments while the robot is operating to ensure sustainability of the operation.

Simple, Fast, Automatically Corrects Position

When a needle is changed, the adjuster uses the previously registered program data to automatically adjust tool-tip position. It is also possible to run periodic adjustments while the robot is operating to ensure sustainability of the operation.

Height Sensor

Operation Stability, Quality Improvement

When the workpiece height is changed, the height sensor compensates deviation of the workpiece height and uses previously registered program data to automatically adjust the tool-tip heights position.

Operation Stability, Quality Improvement

When the workpiece height is changed, the height sensor compensates deviation of the workpiece height and uses previously registered program data to automatically adjust the tool-tip heights position.

Vision Cam System

Solutions For Complex Requirements

Solutions For Complex Requirements

When workpiece positioning can´t be guaranteed or the position where actual work should be performed shifts; In these kind of cases, this equipment is extremely useful for detecting and adjusting program coordinate position data to the exact workpiece position to ensure reliable quality.

Technical Specification

Brochure Link; http://www.dynetechnology.co.uk/Pdfs/BenchtopRobots.pdf

Brochure Link; http://www.dynetechnology.co.uk/Pdfs/BenchtopRobots.pdf

Model Number JR2200 Series

Range of Operation

X axis 200mm

X axis 200mm

Y axis 200mm

Z axis 50mm

Speed

PTP(X,Y) 5~500mm/sec

PTP(Z) 2.5~250mm/sec

PTP(R) 6~600

PTP(X,Y) 5~500mm/sec

PTP(Z) 2.5~250mm/sec

PTP(R) 6~600

CP(X,Y,Z) 0.1~500mm/sec

Repeatability accuracy

X,Y axis ± 0.01mm

X,Y axis ± 0.01mm

Z axis ± 0.01mm

R axis

Portable weight Work 7kg

Tool 3.5 (6.58 2axes) kg

Teaching method

Remote teaching MDI

Remote teaching MDI

Drive method 5

-

-

phase stepping motor

Control method PTP and CP

Control method PTP and CP

Number of controllable axes

2 axes

2 axes

3 axes

4 axes (360º)

External interface

External input/output IN: 16, OUT: 16

Program capacity

Data memory capacity

6,000 points

or 100 points

6,000 points

or 100 points

Program system Memory card

CPU 32bit

Dimensions

Width 320mm Depth 377mm Height 536(655 tall)mm

Width 320mm Depth 377mm Height 536(655 tall)mm

Weight 18kg

Power source Dual voltage 100~200V

Consumption current 200VA

Working ambient temperature 0~40ºC

Relative humidity 20~95% no condensation

| SKU | J090 |

|---|---|

| Availability | Out of Stock |

| Condition | Used |